Unveiling the Excellence of Aluminum Casting in China: A Comprehensive Guide

In the vast realm of manufacturing, aluminum casting stands out as a pivotal process that plays a crucial role in shaping diverse industries. This article delves into the intricacies of aluminum casting, with a special focus on its landscape in China. Let’s embark on a journey to explore the nuances of this technique, its historical roots, and its current significance in the global market.

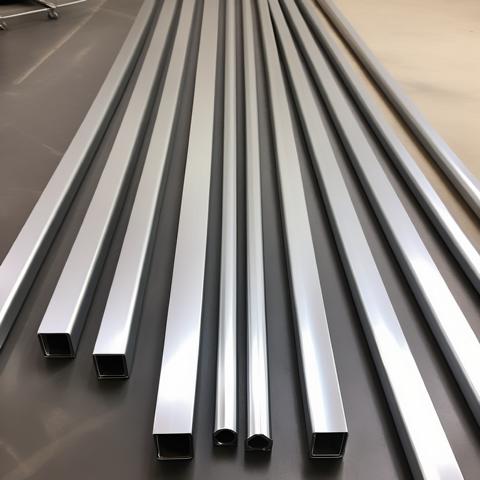

II. Aluminum Casting Process

Aluminum casting is a meticulous process that involves several key steps. Understanding these stages is essential to grasp the complexity and precision required in crafting aluminum components. From melting the aluminum to the final removal of the casting, each step contributes to the production of high-quality components used in various applications.

1. Melting

The process begins with the melting of aluminum, transforming it from a solid state to a molten form ready for molding.

2. Mold Creation

Crafting the mold is a crucial step, as it determines the final shape and specifications of the aluminum component.

3. Casting

During this phase, the molten aluminum is poured into the prepared mold, ensuring that it takes the desired form.

4. Cooling and Solidification

Once cast, the aluminum undergoes a cooling and solidification process to attain the required strength and structure.

5. Removal of Casting

The final step involves carefully removing the casting from the mold, unveiling the finished aluminum component.

III. Aluminum Casting in China

A. Historical Perspective

China has a rich history of contributing to the evolution of various manufacturing processes, and aluminum casting is no exception. The historical roots of aluminum casting in China provide a backdrop for understanding its contemporary significance.

B. Current Status and Trends

Today, China stands as a global powerhouse in aluminum casting, with a thriving industry that continues to evolve. The article will explore current trends, market dynamics, and the country’s prominent position in the global aluminum casting landscape.

C. Key Players in the Chinese Aluminum Casting Industry

An overview of the major players in China’s aluminum casting industry, showcasing their contributions and market influence.

IV. Advantages of Aluminum Casting in China

A. Cost-Effectiveness

One of the key advantages of aluminum casting in China is its cost-effectiveness. The article will elaborate on how China’s manufacturing capabilities contribute to efficient and economical aluminum casting.

B. Technological Advancements

China’s relentless pursuit of technological advancements has propelled the aluminum casting industry forward. From automation to advanced molding techniques, the country remains at the forefront of innovation.

C. Access to Raw Materials

The availability of raw materials plays a crucial role in the success of any manufacturing process. China’s strategic position in sourcing aluminum raw materials enhances its competitiveness in the global market.

V. Challenges and Considerations

A. Environmental Impact

The article will explore the environmental considerations associated with aluminum casting in China, including efforts toward sustainable practices and eco-friendly initiatives.

B. Quality Control

Maintaining high-quality standards is paramount in the manufacturing industry. The challenges and solutions related to quality control in China’s aluminum casting sector will be discussed.

C. Regulatory Framework

An overview of the regulatory landscape governing aluminum casting in China, highlighting compliance requirements and their impact on the industry.

Stay tuned for the continuation of this comprehensive guide, where we’ll delve into the diverse applications of aluminum casting in China and explore case studies showcasing successful projects and innovations.

Welcome to GC Precision Mould, your premier China die casting manufacturer and China Mold Maker. We specialize in producing high-quality plastic molds, die casting molds, and a wide range of die cast parts from materials such as aluminum, zinc, and magnesium.

At GC Precision Mould, we are dedicated to providing our clients with the best possible aluminum die casting and other casting products and services. Our team of experienced engineers and technicians use the latest technology and techniques to ensure that every part we produce meets the highest standards of quality and accuracy.

Our products are widely used in a variety of industries, including automotive, consumer electronics, medical, and industrial equipment. We work closely with our clients to understand their specific needs and develop custom solutions that meet their unique requirements.

Whether you need a single plastic mold or a complete die casting production line, we have the expertise and resources to deliver exceptional results. Contact us today to learn more about our services and how we can help you achieve your manufacturing goals.

If you have a project that needs Die casting China for your die casting project or mould suppliers to make injection molding products, contact us to get the best price now.